Spalling: Difference between revisions

Jump to navigation

Jump to search

(Created page with "Spalling is the flaking or loss of small spalls of material on a bearing rolling element (ball) or Raceway as a result of contamination or fatigue. When contaminants...") |

mNo edit summary |

||

| Line 3: | Line 3: | ||

When contaminants in the form of particles get into the bearing, they can get over-rolled by the rolling elements and create indentations in the raceways. The area around these indentation will be subject to cyclic stress and more metal will eventually break away from the raceway. Damage will gradually progress, along with a rise in noise and vibration levels, until the bearing becomes unserviceable. | When contaminants in the form of particles get into the bearing, they can get over-rolled by the rolling elements and create indentations in the raceways. The area around these indentation will be subject to cyclic stress and more metal will eventually break away from the raceway. Damage will gradually progress, along with a rise in noise and vibration levels, until the bearing becomes unserviceable. | ||

<div><ul> | |||

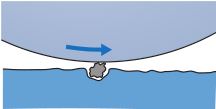

<li style="display: inline-block;"> [[File:Bearing Contamination and Spalling.jpg|thumb|none|Solid contaminants enter the bearing and dent the rolling surfaces. [http://skf.com skf.com] ]] </li> | |||

<li style="display: inline-block;"> [[File:Bearing Sequential Spalling.jpg|thumb|none|Over-rolling of particles with sequential [[Spalling]] starting at the back of the dents on a deep-groove ball bearing inner-ring. [http://skf.com skf.com] ]] </li> | |||

<li style="display: inline-block;"> [[File:Bearing Surface Initiated Fatigue (Spalling).jpg|thumb|none|Spalling over the entire surface of an inner-ring of a deep groove ball bearing. [http://skf.com skf.com] ]] </li> | |||

</ul></div> | |||

[[Category:Glossary]] | [[Category:Glossary]] | ||

Latest revision as of 20:13, 25 November 2016

Spalling is the flaking or loss of small spalls of material on a bearing rolling element (ball) or Raceway as a result of contamination or fatigue.

When contaminants in the form of particles get into the bearing, they can get over-rolled by the rolling elements and create indentations in the raceways. The area around these indentation will be subject to cyclic stress and more metal will eventually break away from the raceway. Damage will gradually progress, along with a rise in noise and vibration levels, until the bearing becomes unserviceable.